Vast experience meets ambitious vision.

Home / News / How to Install and Maintain Fiber Optic Splitter BoxesHow to Install and Maintain Fiber Optic Splitter Boxes

2023.04.14

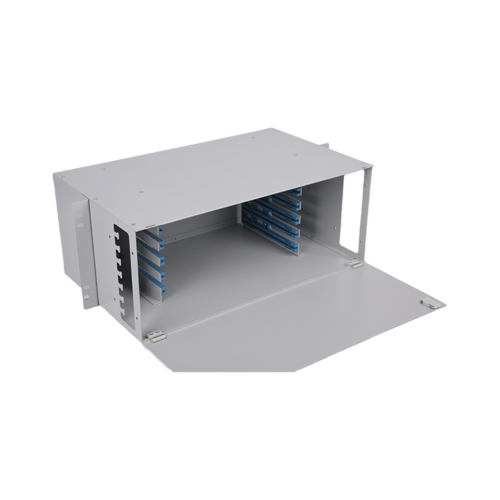

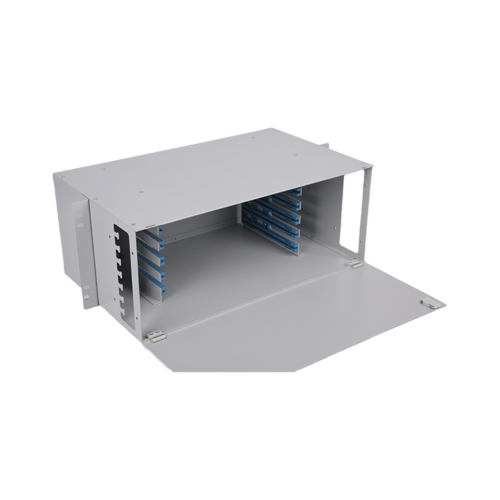

Fiber optic splitter boxes are essential components in modern communication networks, allowing for efficient and reliable data transmission. To ensure optimal performance, it is crucial to properly install and maintain these devices. Here are some key tips for installing and maintaining fiber optic splitter boxes:

Installation:

Choose the Right Location: Fiber optic splitter boxes should be installed in a secure and well-ventilated location, away from potential sources of interference, such as electrical cables, radio transmitters, or sources of heat.

Prepare the Site: Before installation, ensure that the site is clean, dry, and free of dust or debris that can affect the performance of the fiber optic cables. Use a suitable cleaner to remove any dirt or residue from the installation area.

Properly Connect the Cables: Fiber optic splitter boxes must be connected properly to the incoming and outgoing fiber optic cables, using appropriate connectors and splice trays. Follow the manufacturer's instructions carefully to ensure a secure and reliable connection.

Maintenance:

Regular Inspection: Fiber optic splitter boxes should be inspected regularly to ensure that all connections are secure, and there are no signs of damage or wear. Any defects or issues should be addressed immediately to prevent further damage.

Cleaning: Regular cleaning of fiber optic splitter boxes is essential to maintain their performance. Use a suitable cleaner and cleaning tools to remove any dirt or residue from the fiber optic connectors and splice trays.

Protection: Fiber optic splitter boxes should be protected from physical damage or tampering. Use suitable covers or enclosures to protect the devices from dust, moisture, or other environmental factors that can affect their performance.

In conclusion, proper installation and maintenance of fiber optic splitter boxes are crucial for ensuring the efficiency and reliability of communication networks. By following these tips, network administrators can ensure that their fiber optic splitter boxes perform optimally and last for a long time.

Feature Details

GD755-12SC/PC

430mm X 300mm X 43mm

12cires X 1 = 12 cires

GD756-24SC/PC

430mm X 300mm X 87mm

12cires X 2 = 24 cires

GD757-48SC/PC

430mm X 300mm X 132mm

12cires X 4 = 48 cires

GD758-72SC/PC

430mm X 300mm X 177mm

12cires X 6 = 72 cires

related product

-

Fingerprint Reader Office / Home Safe

ZLS-801A

-

Fingerprint Reader Handgun Box

ZLS-817

-

Rifle Safe Electronic Gun Security Cabinet

ZLS-820

-

Solid Wood Construction 3 Drawer Mobile File Cabinet

ZLS-822

-

Splice tray-ribbon 72 cores 208-2D-XP

-

Horizontal Fiber Optic Splice Closure 209F

-

Horizontal Fiber Optic Splice Closure 9008

-

Dome Fiber Optic Splice Closure 208-9

GET STARTED TODAY ?

We Can Help You With

There are many variations of safe, but the majority have services for all types and sizes.

英语

英语 中文简体

中文简体